Miura’s Guide to a Modular Boiler System

The Key to Miura Success: Modular Steam Systems

Traditionally, large traditional fire tube boilers have been the only option for businesses or organizations that needed to produce large volumes of steam for use in heating and processing systems. However, advances in technology and design have created alternative options in the form of modular water tube steam boilers. A modular boiler system is distinct from traditional boilers but the results speak for themselves, often bringing higher efficiency and overall a more flexible steam plant. Here we will take a look at modular steam boiler design to understand how it works and how it’s different from conventional boilers.

Modular Boiler Design: Size Makes a Difference

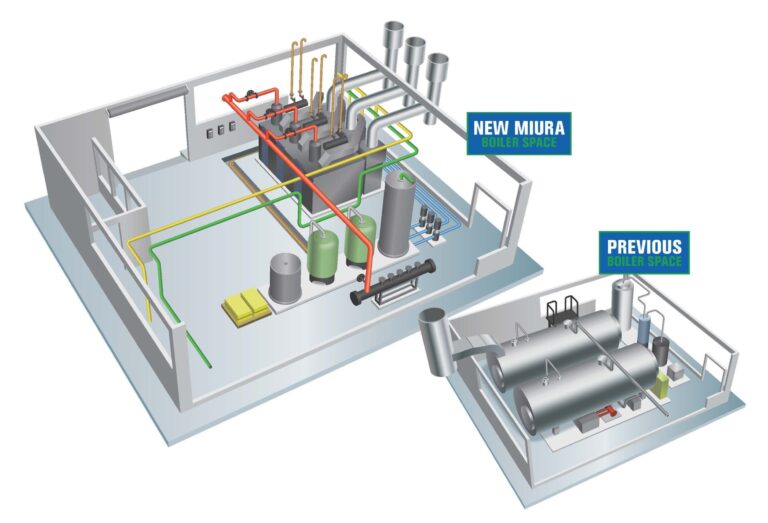

The primary design difference between modular steam boilers and traditional boilers is size. Conventional boilers are massive, needing to be so big in order to meet the peak needs of a company or organization. Modular boilers, on the other hand, are much smaller and more compact. They were designed to address the often limited amount of space in a boiler room or steam plant. In addition to their compact size, modular boilers have no tube-pull space or door-swing space, further reducing their footprint and adding valuable space and flexibility.

Despite being smaller than conventional boilers, modular steam systems are still able to produce the same amount of steam as older boilers. The low-volume pressure vessel makes it possible to achieve output capacities that are comparable to conventional boilers.

How Boiler Size Matters

Modular steam boilers benefit from their smaller size which makes it possible to install multiple boilers in the same space that was previously reserved for just one massive boiler, Miura refers to these systems as MI systems. Often an MI system of multiple boilers are installed as a complete replacement of an old, conventional boiler. Though facilities can add new units to an existing steam system.

Having multiple modular boilers creates more flexibility in your system to handle fluctuating needs and increase the overall efficiency of your boiler system. The smaller modular boilers are designed to work in concert with one another. While also working independently of one another. If the steam need is significant, all of the boilers can function at the same time helping to match the output of a larger boiler. However, when need drops, some can be shut off so that energy and fuel aren’t wasted. This gives a modular boiler system the flexibility to adapt to changing steam needs, while at the same time making it more energy-efficient.

With each boiler in the system having its own burner, boiler control can be granular. Operators can shut down individual boilers when there’s a drop in demand. Each boiler can also be shut down for maintenance without cutting off the entire system. Their smaller boiler size make inspections easier to preform and take only a couple of hours instead of extended full day shutdowns.

How a Modular Steam Boiler System Works

A modular steam boiler system also makes it easy to alternate the boilers that are in use. A master controller can be used to automatically manage the amount of steam being produced by each individual boiler so that draw on one particular unit is not overly taxing any one unit in particular. This sequencing feature improves the efficiency of the entire system and reduces the wear and tear of each individual boiler. This leads to each boiler will last longer and require maintenance less frequently.

Unlike conventional boilers that take a long time to startup, leading them to be left idle when steam needs are low, modular boilers are designed to be turned on and off quickly. Miura’s boilers can go from cold to full steam in under 5-minutes.Resulting in a significant reduction in the amount of water stored and the fuel used when compared to conventional boilers.

The final design difference in modular steam boilers is how easy it can be to add or remove boilers when steam requirements change. Modular boilers take up less room than conventional boilers, and so there is typically room to expand without needing to expand the size of the boiler room or steam plant. A modular boiler system can significantly improve overall steam production compared to the outdated boilers of yesteryear.

Advantages to Modular Steam Systems

Space Saving

Compact, modular boilers save space, which is an immense advantage over space-hogging and outdated fire-tube boilers. With Miura’s technology, our boilers have one of the smallest footprints per output on the market with some models even fitting through standard doorways. In addition to the smaller footprint, Miura’s compact boiler design also eliminates tube-pull and door-swing spaces required by traditional boiler designs.

Flexible Scaleability

As businesses grow, steam needs may increase. With modular boilers, you can add or remove boilers, as required to meet steam and facility demands. Adding a production line? New machinery or processes? A flexible, modular boiler system allows you to add an additional boiler to your existing boiler room to grow your steam output to fit your new parameters.

Construction Savings

Miura’s compact design comes with significant savings on new construction costs. Miura’s boilers require half the space of a conventional fire-tube boiler which amounts to a substantial savings on building costs. Multiple Miura units can fit into the space occupied previously by a single traditional boiler.

Built-in Backups

With Miura’s MI system, your steam plant remains operational during maintenance. Just shut down the boiler receiving service while the remaining units handle your steam requirements. With less than half a day required for routine maintenance, there’s rarely a need for a plant shutdown.

Energy Savings

With the Multiple Installation System (MI), organizations can implement an on-demand steam plant, built to handle current steam loads. While steam needs may fluctuate quickly, the system responds by promptly turning on or off to avoid wasting water or energy. Using Miura’s compact boilers for your steam plant can save energy costs. In fact, you can typically find energy savings of up to 20 percent.

Increased Efficiency

Another benefit of modular boilers is improved efficiency, compared to the old fire-tube design. Miura’s modular boiler systems operate more efficiently at lower loads. So, when facilities don’t require maximum capacity on a year-round or even daily level a modular boiler system can benefit your company.

Interested in how a Modular Steam System could improve your business?

Request a Quote today! >>>