The Connected Boiler Room: Smart Controls & Monitoring

The Connected Boiler Room: Smart Controls & Monitoring

Key to an efficient boiler room, with minimal down-time and consistent steam production, is a well controlled and monitored one. Losing steam production, even for a few hours can completely disrupt your business operations, especially if your boiler room is offline indefinitely waiting for servicing. Miura’s smart boiler controls and monitoring systems helps your boiler stay efficient.

While a watched pot may not boil, a well monitored boiler system runs just right.

An effective monitoring and control system will keep you on top of maintenance needs, by providing concise real-time data that helps alert your team of any potential issues before they become a serious problem. It should be easy to use and help you monitor your steam load and feed water conductivity; this is especially important for any business with fluctuating steam load demands.

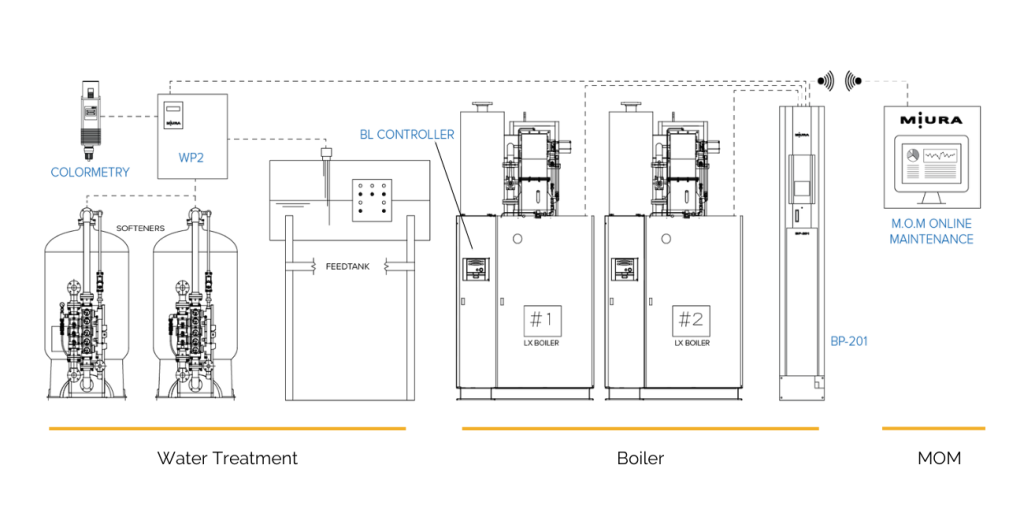

Miura Canada’s modular water-tube boiler systems leverage several smart controls and monitoring systems to streamline boiler room monitoring, maintenance, and operations. Miura helps you save money and get the most out of your boiler with our BP Panel and BL Controller. While Miura’s Colormetry and WP2 systems are there to help you closely monitor your Water Treatment systems for chemical and hardness levels.

In this page, find a guide to Miura’s Boiler Controls and Monitoring devices that keep your steam and water treatment systems preforming at top efficiency. Explore each device in more detail to review its benefits, including Miura’s smart controls for modular steam boilers.

Boiler Controls

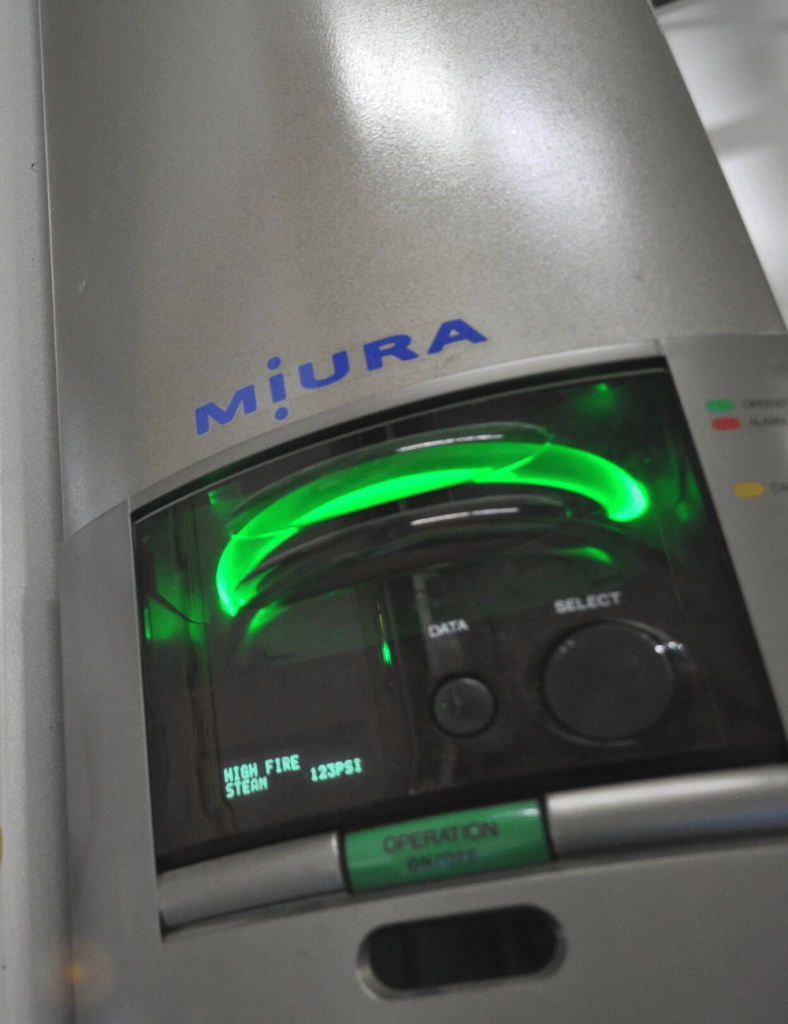

BL Controller

The heart of a Miura boiler

BL Controllers are the control interfaces attached to every Miura boiler. The BL Controller’s microprocessor controls all aspects of the boiler unit. The BL Controller makes it easy for boiler operators to monitor and manage each steam boiler configured in their system. It has an LCD screen that displays current settings and data, monitors real-time data through advanced diagnostics and oversees each boiler’s safety system using a simple stop-light system for alerts. For minor issues, a yellow “caution” light appears on the device display and for serious problems, the BL Controller displays a red “alarm” light.

BP-201

The key to multiple installation

The BP Panel is the core of any Miura Multiple Installation. It acts as a central communication hub for the entire system, displaying the status of all connected devices, including boilers, feedwater systems, and water treatment equipment. The BP Panel determines the most efficient way of operating multiple boilers while achieving the target pressure for the system. This can prolong the life of the entire system by rotating boiler priority, which helps achieve equal runtime levels across multiple boilers. It also provides centralized safety alerts to mitigate any unexpected downtime

Not sure where to start?

Get a Personalized Quote

Water Treatment

WP2

Water Treatment Panel

Good water quality and therefore proper water treatment is the key to a boiler’s long life. Managing hardness reduces scale and improves efficiency. The WP2 Water Treatment Panel helps your team manage water treatment for your Miura system by acting as a control hub for all the water treatment components in this system, testing and detecting the incoming water quality levels through taking constant automated samples from Miura’s Colormetry Hardness detector.

Colormetry

Hardness Detector

Traditionally, manually determining water hardness is time-consuming and unreliable. That’s where a Miura Colormetry Hardness Detector comes in. Calcium and magnesium scale deposits left behind by hard water are one of the leading causes of unexpected boiler downtime. The Colormetry unit’s hardness sensors help prevent scale buildup, reducing the risk of debilitating and costly shutdowns. The Colormetry's sensors can communicate with the BL Controller to further streamline the process, making it easy for your team to adjust water treatment in real-time.

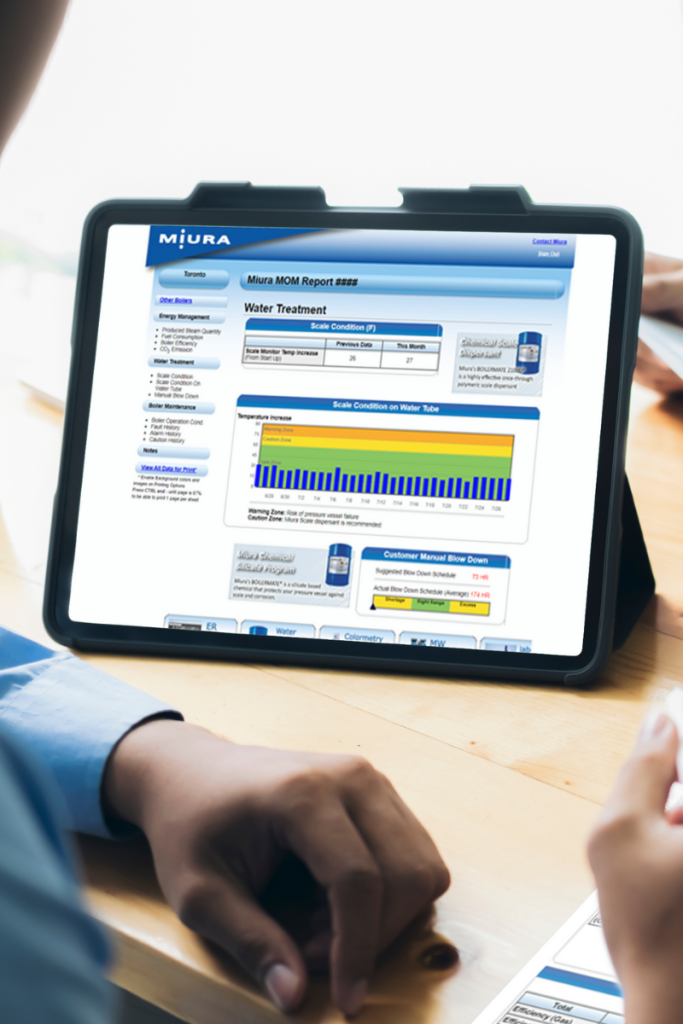

Online Monitoring

MOM

Miura Online Maintenance

The Miura Online Maintenance (MOM) system monitors your boiler operating conditions for easy troubleshooting should any problem arise. The MOM system works with all other Miura control systems to capture real-time data about your systems performance and operating conditions. MOM uses a dedicated line to directly connect to your boiler and keep your information protected. This information can be gathered from the Miura BL controller at any time to assist with troubleshooting. Our MOM centre can monitor boiler operation to check details on boiler status, water level, temperature readings and steam pressure. The reports give clients and reps insights regarding the Steam generated, Boiler Efficiency, Fuel consumption, Scale condition and Blowdown condition.

*By signing up you are opting in to updates and news from Miura Canada