ABC’s of Boiler

The « ABC’s of Boiler » is a good reference tool that defines some of the most common basic boiler terms used in the boiler industry in easy-to-understand language. The terms are listed in alphabetical order and can also be accessed by choosing a letter here:

A

Auto Bottom Blowdown – Auto Bottom Blowdown reduces the frequency of manual blowdowns. This is particularly important when the steam requirement does not allow stopping the boiler for a full blowdown. This option automatically blows down at set intervals and keeps the bottom header from accumulating sludge. It also opens the valve in case of excess concentration in the boiler. (Miura option)

B

Blowdown – The discharge of water contained within the boiler.

Boiler efficiency – The ratio of useful heat output from a boiler to the energy input from fuel, indicating how effectively the boiler converts fuel into usable heat.

Boiler makeup (water) – Treated water that is supplied to the boiler, or the act of sending this water.

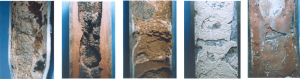

Boiler scale – Scale is a layer of solidification/calcification that forms on the surface of the boiler water tubes.

C

Carry over – The unwanted discharge of moisture or impurities in the steam.

Cavitation – A situation where air enters a pump and prevents normal operation.

Check valve – a valve that permits flow in one direction only.

Combustion – The chemical process of burning fuel within a boiler, typically producing heat energy and exhaust gases as byproducts.

Condensate – The liquid formed when steam cools and condenses, often returned to the boiler as feedwater.

Corrosion – The gradual degradation of metal surfaces in a boiler due to chemical reactions with water, steam, or other substances.

D

Dearator – A device used to heat the boiler makeup water in order to reduce the level of oxygen dissolved in it.

Draft – The flow of air through a boiler, crucial for maintaining proper combustion and removing flue gases from the system.

E

Economizer – A heat exchanger in a boiler that preheats feedwater using exhaust gases, improving overall efficiency.

Efficiency – The ratio of useful output energy to input energy in a boiler, indicating how effectively the boiler converts fuel into usable heat.

Equivalent evaporation – The mass of steam generated in one hour when water at 212°F is changed into steam at 212°F.

F

Feedwater – water sometimes preheated or purified and supplied to a boiler as for steam) or still.

Flue gas – The exhaust gases produced during combustion in a boiler, containing various byproducts such as carbon dioxide, nitrogen oxides, and water vapor.

Fuel – Any substance burned in a boiler to produce heat energy, such as natural gas, oil, coal, or biomass.

G

Gauge – An instrument used to measure and monitor parameters such as pressure, temperature, and water level within a boiler.

Gas-fired – Refers to boilers that use natural gas or other gases as fuel for combustion.

H

High fire – A condition wherein the boiler is operating at maximum combustion

performance.

Heat exchanger – A device used to transfer heat between two fluids without them coming into direct contact, such as heating feedwater using hot flue gases in a boiler.

Header – A manifold or chamber in a boiler that distributes fluid (typically steam or water) to different parts of the system.

I

Insulation – Material used to reduce heat loss from a boiler, improving energy efficiency and protecting personnel from burns.

Ignition – The process of starting combustion in a boiler by introducing an ignition source to ignite the fuel.

J

K

L

Load – The demand or amount of steam required by a system or process from the boiler.

Low fire – A condition wherein combustion takes place at between 33 to 65% of maximum

combustion performance. (firing rate depends on models)

Low water level interlock – The action of preventing ignition when the normal water level has not been achieved.

M

Main ignition – Ignition of the main burner.

Maintenance – Regular upkeep and inspection of a boiler system to ensure safe and efficient operation, including cleaning, repairs, and component replacement.

N

Natural gas – A commonly used fuel source for boilers due to its availability, cleanliness, and relatively low cost.

O

P

Pilot ignition – Ignition of the pilot burner.

Pilot only – A condition wherein only the pilot burner is lit.

Post-purge – Purging with air from the boiler’s combustion chamber after the end of

combustion.

Pre-purge – Purging with air from the boiler’s combustion chamber before the start of combustion.

Pressure – The force per unit area exerted by a fluid (such as steam or water) within a boiler system, measured in pounds per square inch (psi) or bar.

Propane – A colorless, odorless gas used as a fuel in boilers and other heating appliances, typically stored in pressurized tanks.

Q

Quality control – The process of ensuring that materials, components, and finished products meet specified standards and requirements in boiler manufacturing and operation.

R

Relief valve – A safety device in a boiler that automatically opens to relieve excess pressure or temperature, preventing equipment damage or failure.

Regulator – A device used to control or regulate the flow, pressure, temperature, or other parameters within a boiler system.

S

Safety valve – an automatic valve used to release excess pressure within the boiler.

Scale – The buildup of water impurities such as calcium and magnesium on water

tubes.

Sludge – Impurities that precipitate inside the boiler.

Soft water – Water that has had calcium and magnesium removed.

Steam – The vaporized form of water produced by a boiler when heated above its boiling point, used for various industrial processes such as heating, power generation, and mechanical work.

T

Temperature – The degree of hotness or coldness of a substance, such as water or steam, within a boiler system, typically measured using thermocouples or thermometers.

Turndown ratio – The ratio of maximum to minimum boiler output capacity, indicating the range over which the boiler can operate efficiently and reliably.

Thermocouple – A temperature sensor consisting of two dissimilar metal wires that produce a voltage proportional to the temperature difference, commonly used in boiler control systems.

U

Untreated water – Water that has not been treated

V

Valve – A device used to control or regulate the flow of fluids or gases within a boiler system, such as isolation valves, control valves, or safety valves.

Ventilation – The process of providing fresh air to a boiler room or enclosure to maintain safe levels of oxygen and remove combustion byproducts or other contaminants.

Vacuum breaker – A device used in boiler systems to prevent backflow or siphoning of fluids, maintaining system integrity and safety.

W

Water tube -A tube making contact with combustion gas on the outside, and through which boiler water flows.

Water treatment – The process of conditioning boiler feedwater to prevent scale formation, corrosion, and other water-related problems, typically involving chemical additives, filtration, and purification.

X

Y

Z

Resources : LX/EX Operation Manuals ; Merriam Webster Dictionary; Basic boiler terminology; Miura boiler options