Miura Boilers vs Traditional Boilers: More Power, Half the Footprint

How Miura Boilers Deliver the Power of Large Boilers—with Half the Footprint

When it comes to industrial steam generation, many facilities assume that bigger is better. However, traditional large firetube boilers come with limitations that can lead to inefficiencies, increased costs, and safety concerns. Miura boilers vs traditional boilers is a key comparison that highlights why Miura’s modular steam system is a smarter, more flexible solution. Miura boilers meet the same steam demands while improving efficiency, safety, and operational flexibility. Here’s how Miura boilers vs traditional boilers stack up and why businesses are making the switch.

1. Scalability & Redundancy

One of the biggest advantages of Miura’s modular system is its ability to scale with demand. Miura boilers vs traditional boilers is a comparison that reveals a major flaw in large firetube systems: they operate as a single unit, meaning facilities are dependent on one large system. If it goes down, production halts. In contrast, Miura’s multiple small boilers allow for redundancy—if one boiler needs maintenance, the others continue running, ensuring uninterrupted steam supply.

Additionally, Miura boilers can be turned on or off based on demand, avoiding the inefficiencies of running a large boiler at partial capacity. This “right-sizing” capability significantly reduces energy waste and operating costs.

2. Faster Steam Generation

Traditional firetube boilers can take hours to reach full steam capacity, leading to delays and wasted fuel during warm-up periods. Miura boilers vs traditional boilers is a key discussion point in steam efficiency, as Miura boilers utilize on-demand steam technology that allows them to reach full operating pressure in just 5 minutes. This quick start-up time provides immediate steam when needed, reducing downtime and improving productivity.

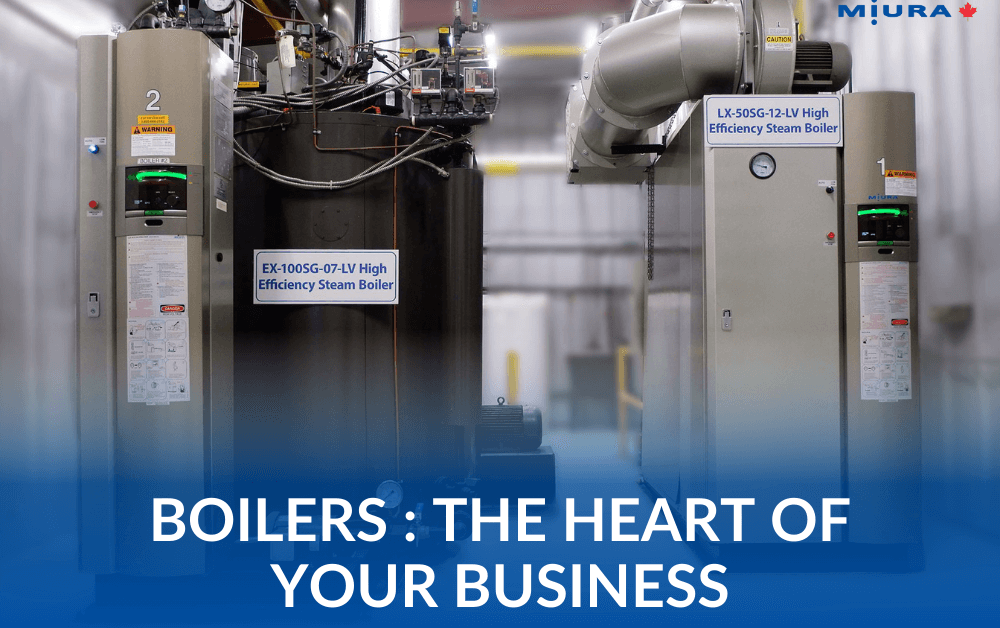

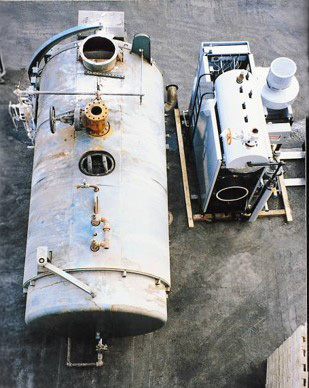

3. Space-Saving Design

Large boilers require extensive floor space, often limiting a facility’s ability to expand operations or install additional equipment. In the debate of Miura boilers vs traditional boilers, Miura’s compact footprint stands out—it takes up 50% less space than traditional firetube boilers. This design allows businesses to maximize usable floor space for production, storage, or future expansion.

4. Fuel & Cost Efficiency

One of the biggest drawbacks of large firetube boilers is their inefficient fuel consumption. They often require constant operation to maintain steam pressure, even when demand is low, leading to wasted energy and excessive fuel costs.

Miura’s modular system, however, matches steam output with actual demand, meaning boilers only fire up when needed. When comparing Miura boilers vs traditional boilers, it becomes clear that Miura’s efficiency results in lower energy bills while maintaining the same steam output.

5. Enhanced Safety Features

Large firetube boilers operate with high-pressure, large-volume water content, which increases the risk of catastrophic failure in the event of a rupture. The high water content means a significant explosion risk, requiring additional safety precautions and frequent inspections.

Miura boilers, designed with low water content, dramatically reduce the risk of explosion. The Miura boilers vs traditional boilers safety comparison highlights how Miura’s low water content means far less stored energy, making them inherently safer than traditional systems.

6. Environmental & Regulatory Benefits

With growing concerns over emissions and sustainability, many industries are looking for ways to reduce their environmental impact. Large boilers often produce high levels of NOx (nitrogen oxides) and CO2 emissions, contributing to air pollution and climate change.

When analyzing Miura boilers vs traditional boilers, Miura’s low-NOx operation stands out, significantly reducing emissions while still providing the necessary steam output. Many facilities switching to Miura find it easier to comply with environmental regulations and reduce their carbon footprint.

7. Maintenance & Longevity

Maintaining a large firetube boiler can be expensive and time-consuming, requiring frequent shutdowns for cleaning, inspections, and repairs. These maintenance requirements often lead to production downtime, further increasing operational costs.

Miura’s modular system makes maintenance more efficient and cost-effective. Individual boilers can be serviced one at a time without shutting down the entire system. With proper water treatment and routine maintenance, Miura boilers vs traditional boilers comparisons consistently show that Miura boilers provide long-lasting performance with minimal disruptions.

The Bottom Line: Miura Boilers vs Traditional Boilers

Traditional large boilers have long been the industry standard, but they come with inherent inefficiencies. Miura boilers vs traditional boilers reveals an innovative approach to steam generation that offers a more efficient, flexible, and cost-effective alternative. With faster start-up times, lower operating costs, increased safety, and environmental benefits, Miura boilers are proving that bigger isn’t always better.

As industries continue to prioritize efficiency and sustainability, the shift from large firetube boilers to Miura’s modular, on-demand steam system is becoming the preferred choice. If your facility is looking to reduce costs, improve reliability, and enhance safety, it might be time to rethink your steam generation strategy with Miura boilers.

Get expert advice on sizing your boiler room

Founded in Japan in 1927, Miura Boilers has grown to be one of the largest industrial steam boiler manufacturers in the world. Miura Canada has been manufacturing boilers for North America since 1987 and has a team of experts who can help you with all your boiler room needs.