In-Service Efficiency

In-Service Efficiency: Setting Miura Apart

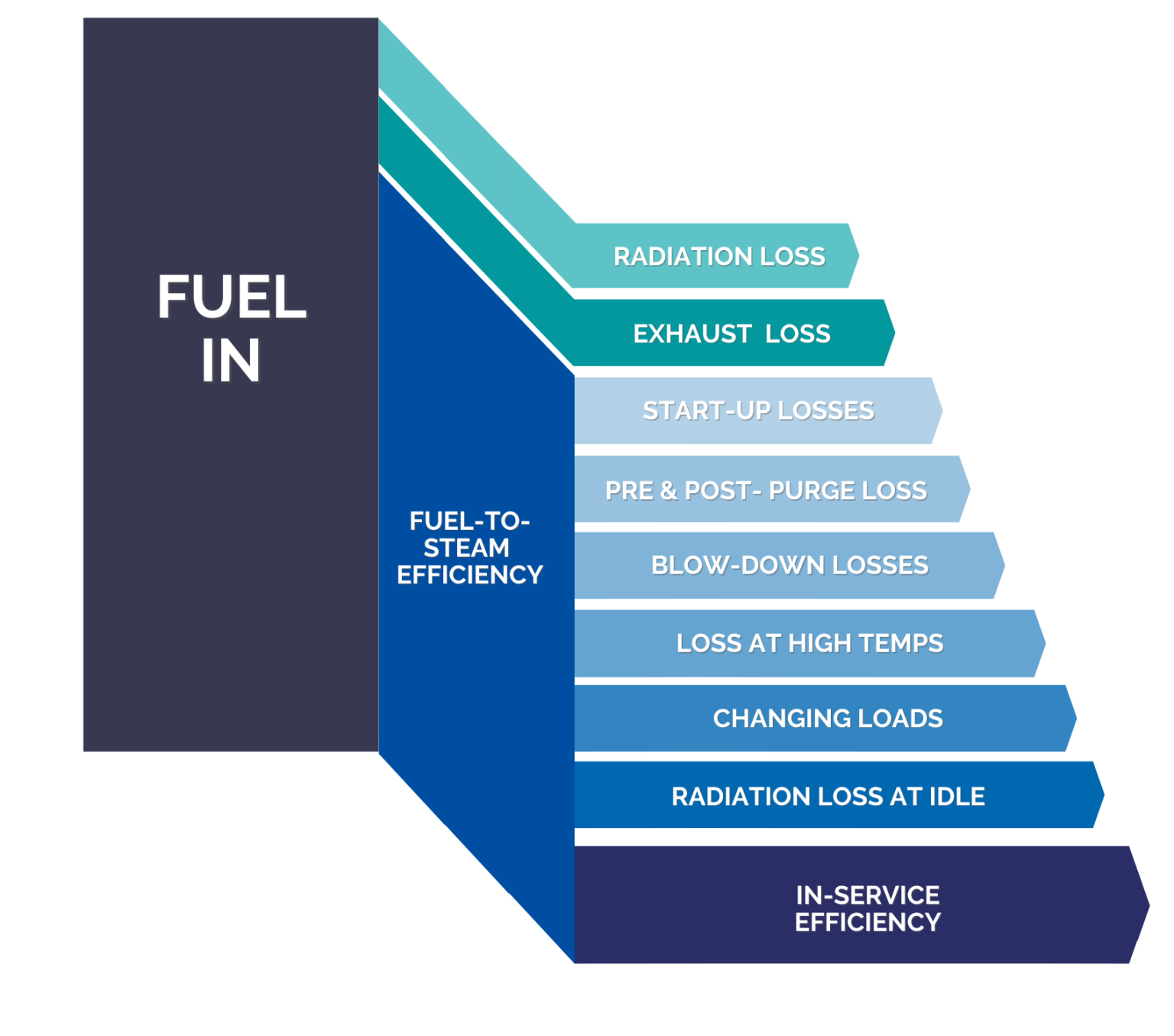

Today’s businesses are maximizing efficiency across all divisions and steam boiler efficiency is a key. A popular measurement for boiler efficiency is fuel-to-steam efficiency. However, fuel-to-steam efficiency doesn’t always tell the whole story. Fuel-to-steam efficiency only relevant when a boiler is working at maximum capacity. Most boilers are not run at maximum capacity 24/7, and so the fuel-to-steam measurement does not take into account; energy losses that may take place while a boiler is running in standby mode, during startups, or during blowdowns are not accounted for with fuel-to-steam efficiency, making it an imperfect method of calculating the overall efficiency of a boiler system.

In-Service Efficiency is a measure of overall performance, no matter your load profile. High In-Service Efficiency is the level of performance every Miura Boiler customer can expect from their system. This standard of excellence has been established based on taking all factors of the boilers operation into account.

Miura has developed the term “In-Service Efficiency” to describe:

- Combustion Efficiency

- Thermal Efficiency

- Fuel-to-Steam Efficiency

It is a comprehensive measurement of efficiency which is based upon an operating model and is the “bottom line” efficiency. It reflects how well a particular boiler design handles a real-world parameters and measures the overall performance of a boiler based on what it is actually being asked to do.

In-Service Efficiency: The resulting efficiency of a boiler when the total operation cycles are considered such as: time of day, day of week, load volume and standby status.

Highest In-Service Efficiencies in the Industrial Boiler Industry

Based on today’s fuel costs, the average dollar savings Miura customers enjoy in steam production is approximately 20% over other boiler designs. At 10% to 40% fuel savings, Miura can save an estimated $200,000 per year in fuel for a typical 600 BHP steam system with the price of natural gas at $0.90/therm.

In the above chart you can see how Miura compares in-service efficiencies against both firetube and watertube boilers of other brands. Whereas the fuel-to-steam efficiency between Miura boilers and other boilers may be close, Miura boilers have an in-service efficiency roughly 20% better than comparable boilers.

Miura’s boiler design results in optimal heating surface transfer with minimal water content for fuel-to-steam efficiencies of 85%. Using less water than other boilers also helps to maximize heating surface transfer. This helps to improve in-service efficiency but may not show up when measuring fuel-to-steam efficiency. Although typical firetube designs can deliver up to 83% fuel-to-steam, studies comparing actual efficiencies have shown Miura averages 10% to 40% in fuel savings over standard firetube designs. Over time, using boilers that focus on maximizing in-service efficiency can help save a significant amount of money. Based on today’s fuel costs, the average dollar savings Miura customers enjoy in steam production is approximately 20% over other boiler designs. Businesses with Miura boiler systems can save an estimated $200,000 per year in fuel for a typical 600 BHP steam system with the price of natural gas at $0.90/therm.

*By signing up you are opting in to updates and news from Miura Canada