Industrial Steam Boiler Basics

INDUSTRIAL Steam Boiler Basics

WHAT IS A STEAM BOILER?

A boiler is a closed vessel in which water or other liquid is heated until steam or vapour is generated.

Industrial boilers are used to produce steam or heat water to provide heat for process heating, sterilization and many other applications that are vital to industrial facilities.

STEAM BOILER TYPES

There are two main boiler types for Industrial steam boilers and each type has its own pros and cons.

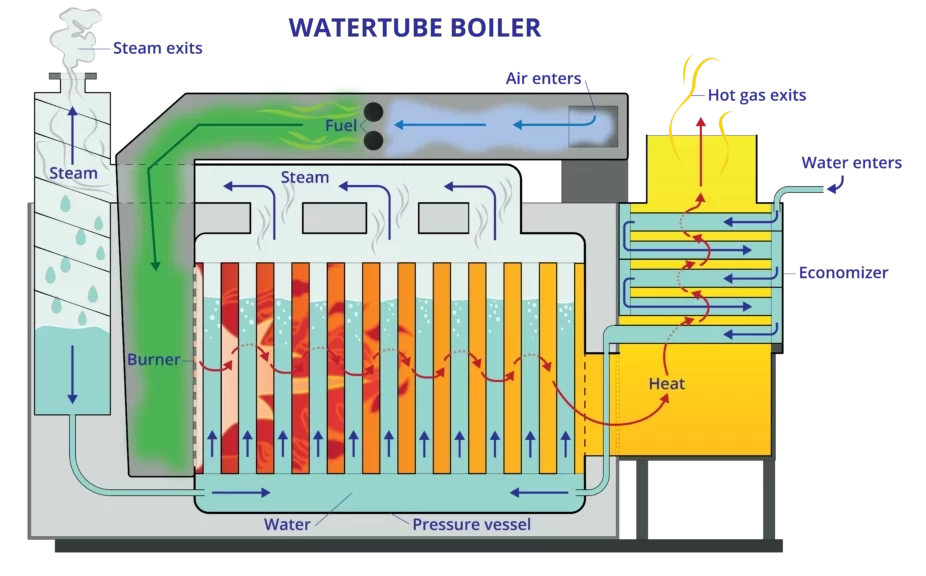

WATERTUBE BOILER

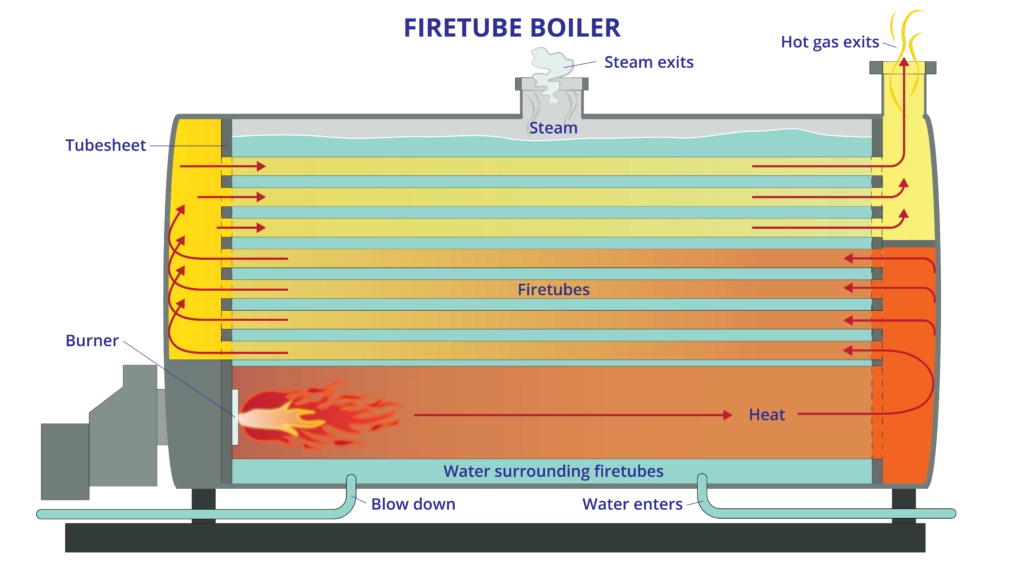

FIRETUBE BOILER

Hot gases pass from a fire through one or more tubes running through a sealed vessel of water. Easier to construct but is not as thermally efficient. The fluctuation of load cannot be easily handled and the rate of steam generation is low. Limited for low to medium pressure applications.

Industrial Steam Boiler Basics

WHAT ARE INDUSTRIAL STEAM BOILERS USED FOR?

Industrial boilers are utilized in many different industries. We have to agree that heat is vital to our everyday lives. We use heat in most facilities whether it be for heating a building or for other industrial processes such as food refining and meat processing, food, paper and cardboard manufacturing. Other industries like commercial laundries and hospitals use steam as a heat source and for cleaning and sterilization, the boilers are critical for what you do. The steam generated is used in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.AUTOMOTIVE INDUSTRY

Steam is often required for sterilization, vulcanization, and other manufacturing processes that require fluctuating load demands.

FOOD & BEVERAGE

Heat is the heart of industrial food processes. the food industry needs heat at every stage of the process.

BREWERIES & DISTILLERIES

Steam is used in the brewing process like boiling, mashing and fermentation. It is also used to maintain high sanitation levels and cleaning utensils.

CHEMICAL PROCESSING

Steam is used in process heating, power generation, atomization, cleaning and sterilization , moisturization and humidification.

HOSPITALS and HEALTHCARE

Steam is commonly used in the healthcare industry for sanitation purposes. It helps kill harmful microorganisms on reusable medical and surgical equipment. Steam is also used to providing heat for the buildings and humidification.

INDUSTRIAL FACILITIES

A huge number of industries use steam as a heat source and for cleaning and sanitation. Steam is also often used in the manufacturing processes themselves and in powering equipment.

LAUNDRY FACILITIES

Steam helps shorten the duration of washing process, it is helpful in removing odors and refreshes the fabric. Steam helps remove the contaminants and heats and moistens the area to help in the cleaning and sterilization

TEXTILE MANUFACTURING

Steam is used in major stages in the Textile industry. From fiber production, weaving , dyeing, drying, printing, ironing and washing, Steam is without a question one of the most important part of textile manufacturing process.

INDUSTRIAL Steam Boiler Basics

HOW MIURA STARTED

Miura has been setting standards in boiler technology since we started developing our Z boilers in Japan in 1959. The concept behind the name was that since “Z” is the last letter in the alphabet, it would signify that “Nothing can come after this”.

Now, more than half a century later, we have designed and manufactured Industrial steam boilers that are currently available in 24 countries and have been trusted by large companies worldwide. LEARN MORE

UNDERSTANDING BOILER LOADS

BTU is the rating indicating the maximum capacity of a boiler. When a boiler operates at its maximum rated capacity, it is referred to as maximum load. If the load varies from hour to hour, it operates at a varying load.

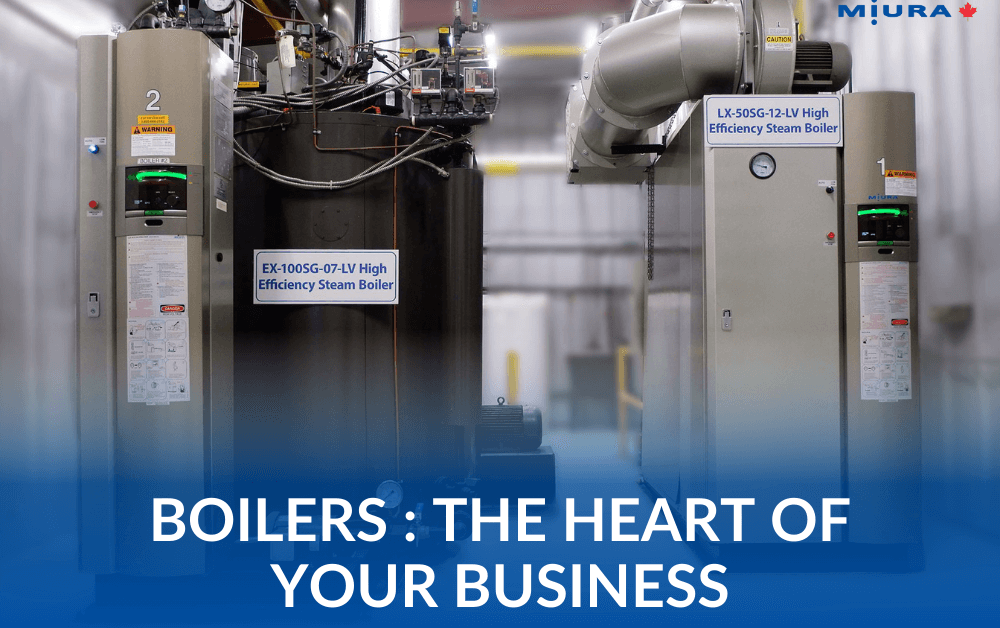

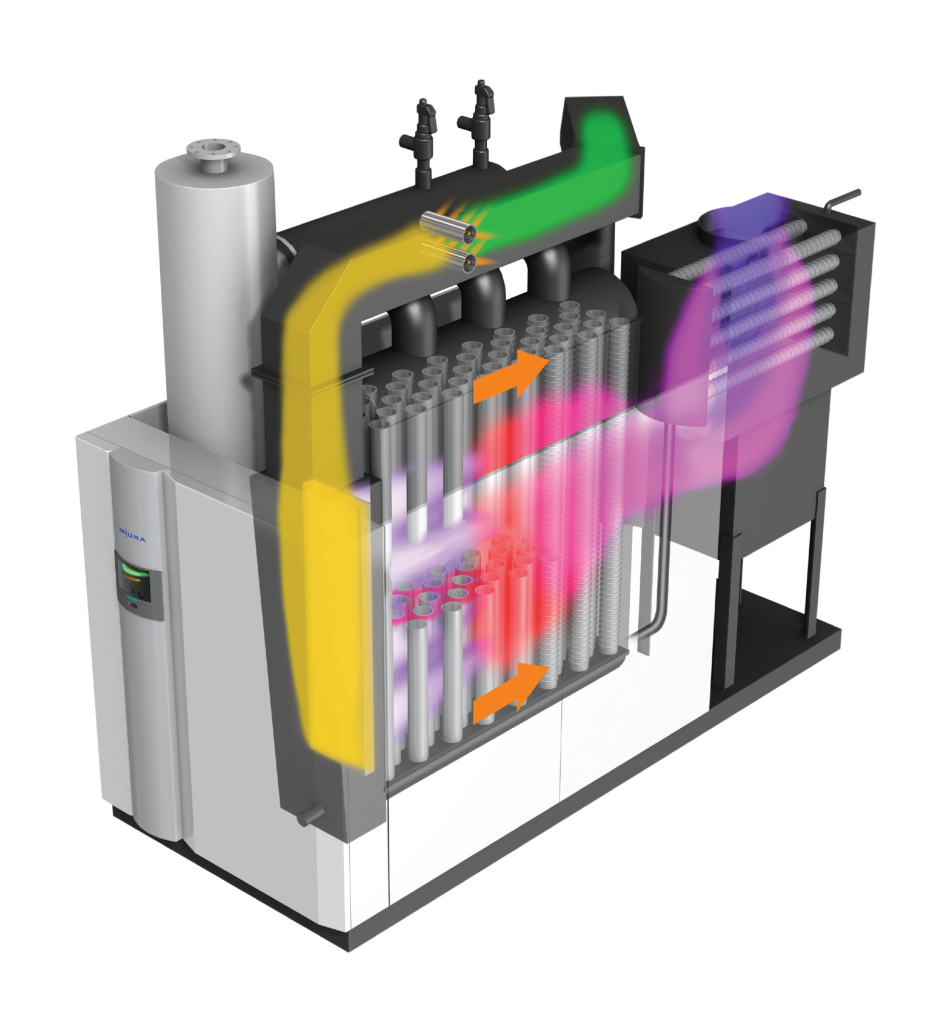

The Miura modular concept achieved with quick start-up and compact design of the LX series allows optimized efficiency and flexible operation of the steam system. Multiple units work together to share the steam load and keep up with the changing demands in seconds. REQUEST A STEAM LOAD STUDY

Share