Modular Systems for Peak Hospital Efficiency

Flexible Steam for an Efficient Hospital Energy System

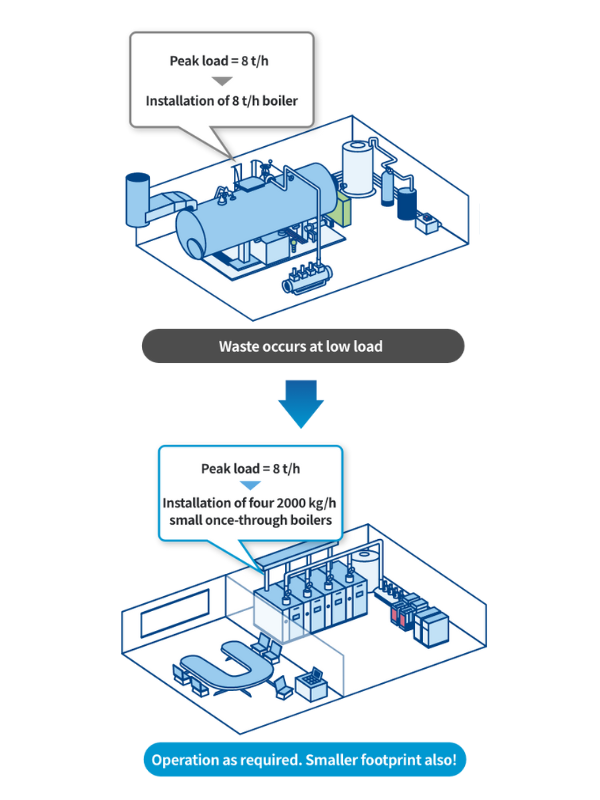

A modular boiler system functions like a single boiler, despite being made up of individual boilers that run independently with their own burners. Because the units can be turned on and off depending on the precise amount of steam needed at any given time, a facility never produces more steam than it needs. This improved efficiency helps hospitals conserve energy and save money. In fact, facilities that make the switch to a Miura modular boiler system enjoy an average 20% savings in annual fuel costs.

In addition to the improved efficiency and outstanding cost savings, there are several other reasons why hospitals choose Miura modular boiler systems:

Flexible scalability

- Changing facility needs? Add or remove boilers from your modular system with ease.

Speedy start-up

- Our boilers produce on-demand steam from a cold start in less than five minutes.

Monitoring and maintenance

- Avoid downtime and extend the life of your boiler(s) with our user-friendly monitoring and maintenance systems.

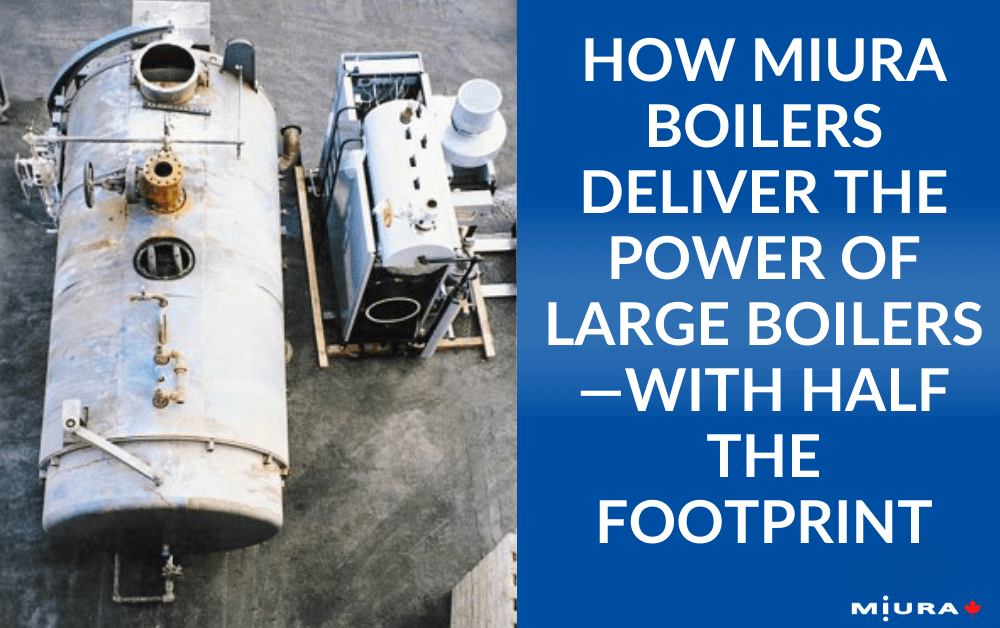

Compact footprint

- Our EX boilers take up 33% less space than a typical firetube boiler, and our LX boilers are even smaller.

Reduced CO2 and NOx emissions

- Miura is a leader in low-emission boiler technology.

Unparalleled safety record

- Miura watertube boilers are safer by design.

Miura's MI Systems

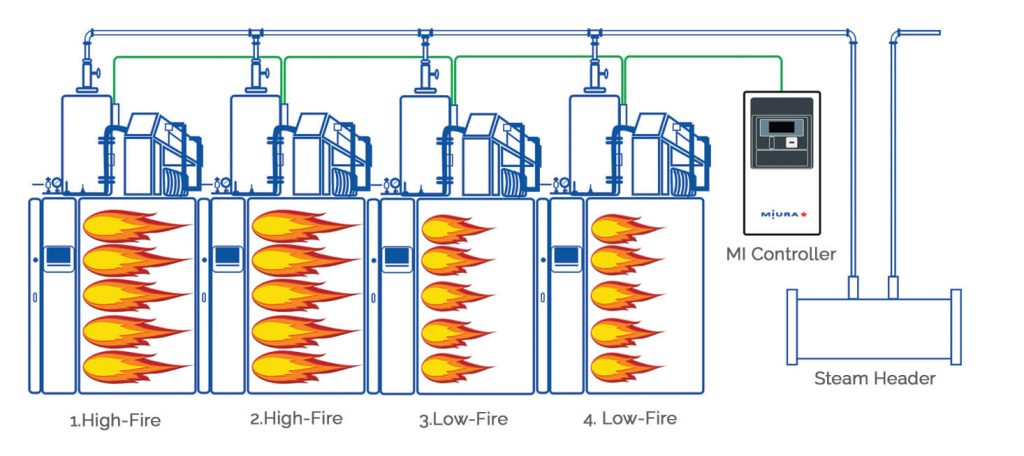

Many facilities take advantage of Miura’s modular boiler systems to fit more lower powered units into the footprint of a large traditional boiler, working in chorus and controlled seamlessly as an MI System. In an MI configuration, the Multiple Installation (MI) System’s master controller intelligently controls all connected boilers to ensure coordinated operation, meeting the required steam load while optimizing efficiency, response time, and boiler longevity.

Features

Utilize modularity to bring On-Demand steam performance to large-scale applications reducing energy consumption required to meet variable loads by dividing the output capacity among multiple units.

- Customize plant size to specific needs

- Automatically stage boilers to meet demand fluctuations

- Save 20% on average in annual fuel costs

- Provide equivalent boiler capacity in less than half the space

- Reduce CO2 and NOx emissions

- Ideal for a wide range of applications from point-of-use to district energy