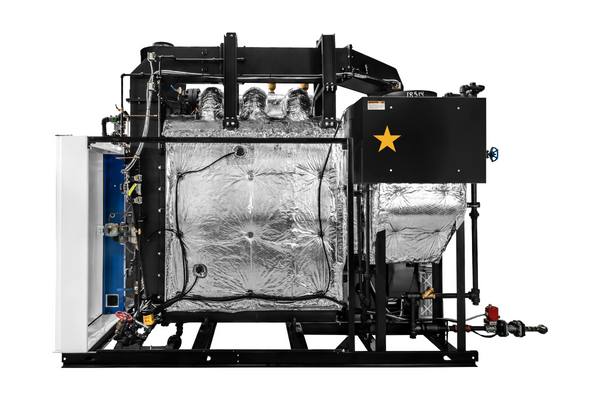

The heat recovery device utilizes exhaust heat to preheat incoming feed water. Above and to the right; the Economizer Water Inlet can be seen. This is where the feed water piping enters the economizer.

Investing in facility infrastructure and getting capital projects off the ground can be difficult. Committing to large spending plans is almost as difficult as engineering and sourcing those plans themselves. This is where efficiency rebates for facility retrofits come in handy. When governments and utilities offer plans to offset renovation or equipment costs to encourage green solutions and improved efficiency it softens the blow of a system retrofit or new purchase.

Both Energir Quebec and Enbridge in Ontario currently have rebate programs for increased boiler efficiency and other green improvements. From boiler economizers to monitoring and control systems these utilities are offering big rebates on features that often come standard in Miura steam solutions. Learn below how Miura’s green technology can help you save up to $150,000 on your renovation.

In Ontario, Enbridge is offering its new Commercial Custom Retrofit Program. Hoping to encourage Ontario businesses to invest in energy-efficient retrofits to reduce their long-term costs and lower their carbon footprint. When your business improves your building’s energy efficiency and lowers your operating costs with boiler and control upgrades you could save tens of thousands of dollars. For a limited time, get 2X the incentives with their Early Bird Offer.

Enbridge’s Early Bird promotion has a short deadline so connect with our team to register with the program before June 30, 2024 to qualify for double incentives on new control systems. The deadline for your project to be in service is Oct. 31, 2024. Miura’s local manufacturing means you can easily have your new efficient steam boiler with an economizer installed in line with the Enbridge program.

| Early Bird Offer | 2023 Average Incentive | 2023 Maximum Incentive |

|---|---|---|

| Controls: $0.50/m3 natural gas saved up to 75% of upgrade costs. (up to a maximum of $100,000.) | $12,500 per project | $100,000 per project |

| High-efficiency boilers: $0.30/m3 natural gas saved up to 75% of upgrade costs. (up to a maximum of $100,000.) | $9,000 per project | $69,000 per project |

*Full Details Available at Enbridge.com

In Quebec, current or new Energir customers may be eligible for a rebate of 75% of their costs when upgrading or retrofitting a boiler with an economizer, micromodulation, or other efficiency upgrades. Boiler economizers recover heat from hot gasses vented into the atmosphere, and can increase the efficiency of your boiler by 85% or more. All of Miura’s boiler systems include a built-in economizer with every model. The economizer captures otherwise wasted heat from the combustion exhaust to preheat the incoming feed water. With this, the Miura LX-Series boiler produces steam using less fuel while operating at increased efficiency.

Energir’s promotion has four upgrades that are available for rebate:

Any single upgrade or combination of the 4 is eligible and stack for added savings!

Measures | Grants | Maximum Amount |

|---|---|---|

Economizer (standard and condensing) | $30 to $300 per boiler BHP | 75% of eligible costs Integrated economizers: maximum $150,000 |

Micromodulation | $30,000 per boiler | 75% of eligible costs |

Combustion oxygen trim | $10,000 per boiler | 75% of eligible costs |

Thermal insulation of equipment and accessories | $30 to $2,200 per unit (The amount depends on the type of equipment/fixture being insulated.) | 75% of eligible costs Maximum $100,000/year |

*Full Details Available at Energir.com

In a boiler, the flue gas is the heated gas that exits the boiler via an exit duct known as the flue. The escaping hot gas is a site of heat loss in the boiler system. Non-condensing economizers work through a basic heat exchange process. They consist of a heat exchange mechanism situated in the flue and are usually finned coils or tubes. As the hot exhaust gases pass across the heat exchange mechanism, heat transfers to the coiled mechanism. The recaptured heat increases the feedwater temperature entering the boiler. As the captured energy heats the feedwater, less fuel is needed to heat the water to the required boiling temperature.

Non-condensing economizers do not lower the flue gas temperature to below its acid dew point (the temperature, at a given pressure, at which gaseous acids such as SO2 in the flue/exhaust gas will start to condense into liquid acid). Depending on the boiler’s fuel, the resulting condensation can contain particles capable of corroding the flue. Keeping the temperature above the condensation point avoids the problem of potentially corrosive compounds.

The heat recovery device utilizes exhaust heat to preheat incoming feed water. Above and to the right; the Economizer Water Inlet can be seen. This is where the feed water piping enters the economizer.

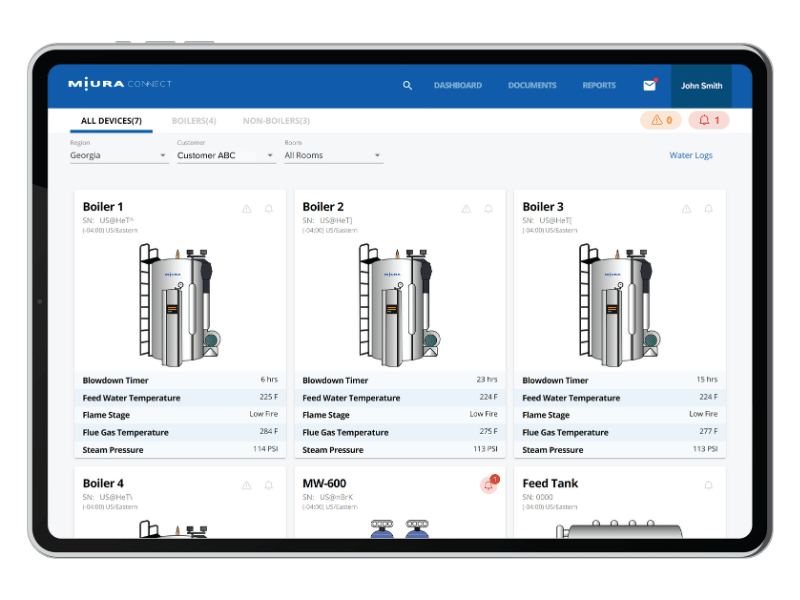

The key to successful boiler monitoring and control is a clear view of not only your equipment but of your business style. Are you in the boiler room daily to check levels? Do you need to have a remote view of your system? What is the hourly, or daily draw on your system? The overall quality of your water? Getting a true handle on your system can guide you to exactly what types of monitoring and control tools you need to employ. From Our BP control panels, Miura Online Mont=itoring, Water Treatment Monitoring &

Miura Connect

Miura Connect is a web-based portal that provides a real-time view of connected equipment in your boiler room. Build custom reports from historic boiler data, monitor chemical and water treatment levels, check in on your system at any time of day from any computer or mobile device, and receive real-time boiler room notifications.